Chapter 3: Spray Application General Guidelines

Airless spraying is the most widely used method of paint application in Factory Built Housing (FBH), Manufactured, and Modular Housing production environments. The best practices in this Handbook for spray application describe general guidelines. To achieve the best results, consult with your supplier for specific recommendations regarding the paint product used in your production process.

See All Chapters

View Chapter 4: Spray Application Working Pressure

Best Practices

General Considerations

Before you begin application, it is important to know your total target film build milage based on the total number of coats involved in your production process. This will allow your supplier to assist you with establishing and maintaining a “Standard of Quality.”

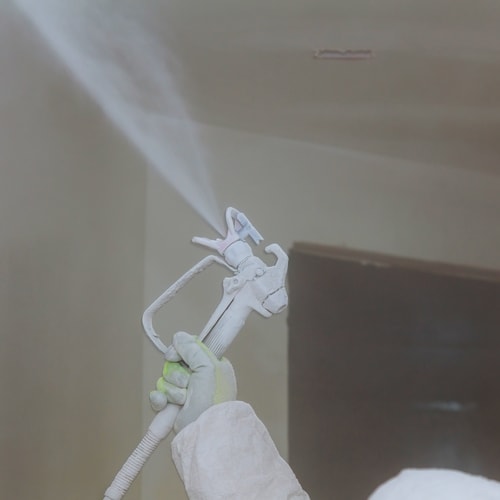

CAUTION: Keep your fingers and hands away from the spray tip while the sprayer is in operation. The pressure at the tip of the spray gun is typically in the range of 3000 psi. At that pressure, paint can cause severe cuts and inject paint into your skin! And, always use the proper Personal Protective Equipment (PPE) for the job.

Explore Masks and Other Personal Safety Equipment

Best Practices

Target Wet Film Thickness

Many production flat wall finishes are formulated to provide reasonable hide and uniformity when applied at a consistent 10 wet mils (combining total applied coats), allowing for a minimum dry film thickness (DFT) of 3 mils.

To achieve reasonable hide, film thickness will vary by product, depending upon both the volume of the product’s solids, and the performance properties of the specific combination of solids used in the formulation. Your supplier should recommend the target milage.

find the right paint for your project

Best Practices

Spray-Only Application

The most efficient way to achieve your target film build is by spray application. When working with a “spray-only” production, drywall mudding and prep work need to be flawless. Surface variations and imperfections are not easily concealed by sprayed paint.

Textured wall finishes, such as knock-down, are often utilized because these finishes are more forgiving. Using an airless sprayer such as the Graco TrueCoat Pro II handheld sprayer is a quick and convenient method to touch up spray-only finishes. Foam rollers are recommended for touching up spray-only finishes because foam rollers do not create an obvious applied texture variation, such as the stipple effect of a roller nap.

View Other Painting Supplies and Equipment

Best Practices

Spray and Backroll

When applying paint using the “spray and backroll” technique, we recommend using Graco’s JetRoller, when available. The JetRoller combines rolling and spraying into one action, saving time and labor on spray/backroll projects. Use a wet film gauge after the backroll is performed to achieve the desired target milage.

- The quality of the finished surface that has been sprayed and backrolled is greatly dependent upon the initial spray coat. When the spray is applied correctly to create a uniform film build, the backroll process is relatively quick and easy. Use a ceiling-to-floor downstroke to “lay-off” the material with a slight stipple texture.

- This stipple texture, especially on smooth drywall, allows for the finish to mask the appearance of slight surface irregularities.

- Just as with spray-only application, a foam roller is the tool of choice for touch-ups. A similar nap cover that duplicates the surface texture may also be used. To avoid inconsistencies in the painted surface, follow the same “down-stroke” lay-off direction that was used during the application of the original backroll.

Best Practices

Tip Size

The most common tip size in the production environment is a .015” - .017” diameter orifice tip. However, based upon the experience of the operator and the speed of the applicator, a larger tip may be substituted.

Never exceed the maximum tip size that the equipment can support.

Explore Tip Options

Best Practices

Tip rotation

Because of the high pressure of the paint material as it passes through the tip, spray tips have a limited life. Several factors, including the abrasiveness of the material pressure and the number of hours logged on the sprayer, contribute to the speed at which the spray tip wears out.

For typical production wall finishes, routine spray tip replacement is recommended if the fan size has lost 25% of its original size. Continuing to spray with a worn tip would simply result in a poor quality spray job, and a substantial waste of paint and labor.

find the right Exterior paint for your project

Best Practices

Roller Quality

When backrolling, roller quality can have a tremendous impact on the uniformity of the finish. High-quality rollers produce a uniform coating because they apply material more evenly and they produce less splatter than economy-grade rollers.

If you examine an economy-grade roller, you’ll find that it has a looser, low-density pile, which creates more variation between the highs and lows of the stipple, and poor coating uniformity.

Find High-Quality Rollers of All Sizes

Best Practices

Using the Spray Gun

For the best results, follow these instructions when spraying:

- It is important to "trigger" the gun after arm movement has started and release the trigger before arm movement ends. A more even amount of paint will be deposited.

- Overlap the previous pass by half the width of the spray pattern. At the end of each pass, reverse direction and maintain speed distance, overlap, and triggering.

- Low pressure, which can result from a number of variables, will lead to tailing, or striping along the outer edges of the fan pattern. As pressure further degrades, striping becomes more obvious throughout the entire spray pattern. Too much pressures and/or excessive spray distance results in overspray, fog, and poor material transfer efficiency to the surface.

- Keep the angle of the spray pattern perpendicular to the surface, with the spray tip moving at a consistent distance from the wall, prefereably 10-12 inches away. This will maximize transfer efficiency and help to keep up the production pace. An arched pass will poorly distribute the paint - too heavy in the center of the pass and too light on the ends.

Find the Right Tip for Your Sprayer

Best Practices

Spray Technique

There are several variables that you can control that can affect touch-up appearance and final appearance, as well as the rate of material consumption:

- Know the target mil thickness for the material and application method employed.

- Use a wet mil gauge to set the job standard and to keep you focused on maintaining a uniform milage.

- Establish a standard with consistent use of either spray or roller application.

- Use the correct pressure. Too little pressure will result in an uneven spray pattern. Too much pressure causes excessive overspray and premature tip wear.

More Best Practices

Spray Technique

- Maintain the proper spray distance of 10”-12” from the surface. 20% more material is lost in transfer when moving from 12” to 16”.

- Adhere to the 50% Rule, which dictates that each pass of the spray gun “overlap” the preceding pass by 50%, to maintain a uniform film thickness.

- Backroll immediately following the spray application. Extended delay results in dry-rolling, which pulls material from the surface. When performed correctly, backrolling should be a single pass step to simply “lay-off” the film with a slight texture. For best results use Graco’s JetRoller. The JetRoller combines rolling and spraying into one action, saving time and labor on spray/backroll projects.

See All Pro Painting Supplies